TECHNOLOGY LEADER FOR OVER 50 YEARS

Bertoli Homogenizers

For 50 years, a technological leader in the homogenizer and piston pump sector

SUSTAINABILITY AS A VALUE

Clear activities, with precise timing and resources and related to management objectives that make the ESG Plan a coherent reflection of the Group's policy." [Dr. Fulvio Montipò, President]

Interpump is a large multinational group

Interpump Group is the world's largest manufacturer of high and very high pressure piston pumps and one of the world leaders in the hydraulic sector. The interpump group is a company of men and technicians that is fully and proudly placed among the major world players in the reference sectors.

Lower consumption and greater performance

All our machines are designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

In 2020 Bertoli, with the aim of minimizing the environmental impact, presented EVO-GREEN SERIES.

The HA34 model, in the versions with motors up to 90 kW, features a reduction in water, energy and oil consumption thanks to the new solutions developed in synergy with Interpump.

Homogenizers

Explore Bertoli’s range of industrial homogenizers, designed for the food, dairy, chemical, cosmetic, pharmaceutical, biotechnology, and nanotechnology industries. Our cutting-edge technology ensures a flawless homogenization process, delivering superior-quality finished products. Each homogenizer is engineered for maximum precision, ensuring consistent and high-quality results in every application.

Find out more

Volumetric piston pumps

Bertoli volumetric piston pumps provide reliable solutions for various industrial sectors, including agri-food, canning, and spray drying industries. Designed for applications requiring high levels of hygiene, they stand out for their efficiency and durability.

Find out more

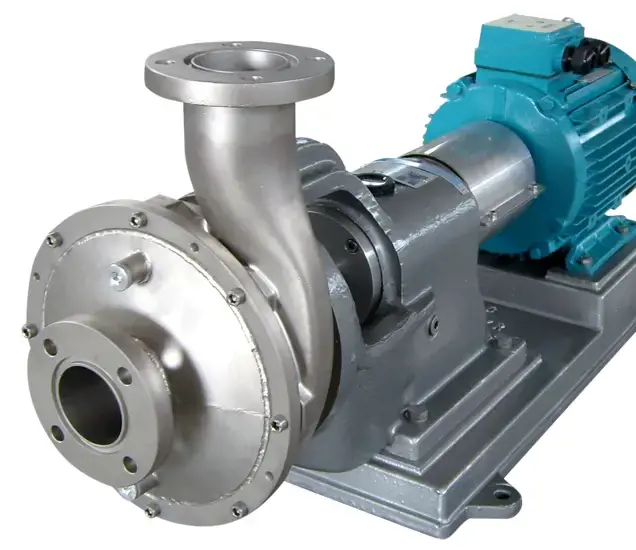

Centrifugal pumps

Bertoli centrifugal pumps are particularly used in the tomato sector and are therefore designed for pumping viscous products. The BE centrifugal pumps have been designed for pumping viscous products and to always ensure a high NPSH in order to avoid the risk of cavitation.

Find out more

Grinder Pumps

Discover Bertoli’s grinder pumps, indispensable for the food industry. The efficiency and quality of the internal blades ensure that the product achieves consistent and fine dimensions. The BT60L grinder pumps are primarily used in the processing of tomatoes and pitted fruit, guaranteeing excellent results. These pumps combine efficient grinding with pumping capacity, ensuring a smooth production process and significantly reducing processing times. Their use maximises the efficiency of pulping machines.

Find out more

Colloidal Mills

Bertoli’s colloidal mills are highly efficient, capable of processing up to 25,000 L/h of product. They specialize in grinding solids and creating emulsions for applications such as plant-based foods, baby food, hummus, soups, sauces, and seaweed. Beyond the food industry, these mills are also ideal for cosmetics, pharmaceuticals, and chemicals.

Find out moreHomogenizers

| Pressure | kW | 100 bar | 200 bar | 250 bar | 400 bar | 600 bar | 1.000 bar | 1.200 bar | 1.500 bar |

|---|---|---|---|---|---|---|---|---|---|

| HA30 | 15 | 5.000 l/h | 2.500 l/h | 1.800 l/h | 1.100 l/h | 800 l/h | 300 l/h | 200 l/h | 200 l/h |

| HA32 | 30 | 8.000 l/h | 5.000 l/h | 4.000 l/h | 2.500 l/h | 1.600 l/h | 700 l/h | 600 l/h | 450 l/h |

| HA33 | 45 | 15.000 l/h | 7.500 l/h | 6.000 l/h | 3.500 l/h | 2.500 l/h | 2.400 l/h | 2.000 l/h | 1.500 l/h |

| HA34 | 90 | 24.000 l/h | 15.000 l/h | 12.000 l/h | 7.500 l/h | 5.000 l/h | 2.400 l/h | 2.000 l/h | 1.500 l/h |

| HA35 | 110 | 35.000 l/h | 18.000 l/h | 15.000 l/h | 9.000 l/h | 5.500 l/h | 3.000 l/h | 2.500 l/h | 1.800 l/h |

| HA36 | 250 | 45.000 l/h | 40.000 l/h | 32.000 l/h | 20.000 l/h | 14.000 l/h | 5.500 l/h | 4.500 l/h | 4.000 l/h |

| HA53 | 400 | 90.000 l/h | 65.000 l/h | 52.000 l/h | 32.000 l/h | 24.600 l/h | 8.500 l/h | 7.500 l/h | 6.000 l/h |

Pumps

| Pressure | kW | 100 bar | 200 bar | 250 bar | 400 bar | 600 bar |

|---|---|---|---|---|---|---|

| PA30 | 15 | 5.000 l/h | 2.500 l/h | 1.800 l/h | 1.100 l/h | 800 l/h |

| PA32 | 30 | 8.000 l/h | 5.000 l/h | 4.000 l/h | 2.500 l/h | 1.600 l/h |

| PA33 | 45 | 15.000 l/h | 7.500 l/h | 6.000 l/h | 3.500 l/h | 2.500 l/h |

| PA34 | 90 | 24.000 l/h | 15.000 l/h | 12.000 l/h | 7.500 l/h | 5.000 l/h |

| PA35 | 110 | 35.000 l/h | 18.000 l/h | 15.000 l/h | 9.000 l/h | 5.500 l/h |

| PA36 | 250 | 45.000 l/h | 40.000 l/h | 32.000 l/h | 20.000 l/h | 14.000 l/h |

| PA53 | 400 | 90.000 l/h | 65.000 l/h | 52.000 l/h | 32.000 l/h | 24.600 l/h |

Related Products

The HA30 from the Evo Line is designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 15 KW

- Pressure (bar): 600

- Capacity (L/h): 5.000

The HA32 from the Evo Line is designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 30 KW

- Pressure (bar): 600

- Capacity (L/h): 8.000

The HA33 from the Evo Line is designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 45 KW

- Pressure (bar): 600

- Capacity (L/h): 15.000

The HA34 from the Evo Line is designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 90 KW

- Pressure (bar): 600

- Capacity (L/h): 24.000

The HA35 from the Evo Line is designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 110 KW

- Pressure (bar): 600

- Capacity (L/h): 35.000

The HA36 is part of the Evo Line and is designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 250 KW

- Pressure (bar): 600

- Capacity (L/h): 45.000

The HA53 is part of the Evo Line and is designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 400 KW

- Pressure (bar): 600

- Capacity (L/h): 90.000

MOLECOLA is part of the Star Line, designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 15 KW

- Pressure (bar): 1500

- Capacity (L/h): 300

The HA34 homogenizer is part of the Star Line, designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 30 KW

- Pressure (bar): 1.500

- Capacity (L/h): 700

The HA34 homogenizer is part of the Star Line, designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 90 KW

- Pressure (bar): 1.500

- Capacity (L/h): 2.400

The HA35 homogenizer is part of the Star Line, designed with a green approach to minimize environmental impact while ensuring energy efficiency and sustainability in liquid processing.

- Power: 110 KW

- Pressure (bar): 1.500

- Capacity (L/h): 3.000

The HA36 homogenizer from the Star Line is designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 250 KW

- Pressure (bar): 1.500

- Capacity (L/h): 5.500

The HA53 homogenizer is part of the Star Line, designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 400 KW

- Pressure (bar): 1.500

- Capacity (L/h): 8.500

The laboratory homogenizer and pilot plant Atomo 3.0 has been designed with 3 pistons for reliable scale-up from laboratory testing to production.

- Power: 4 KW

- Pressure (bar): 1500

- Capacity (L/h): 650

Tabletop single plunger laboratory homogenizer Quark model is designed with 1 piston for reliable scale-up from laboratory testing to production.

- Power: 0,75 KW

- Pressure (bar): 2000

- Capacity (L/h): 3

The PA30 of the Evo Line is designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 15 KW

- Pressure (bar): 600

- Capacity (L/h): 3.000

The PA32 of the Evo Line is designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 30 KW

- Pressure (bar): 600

- Capacity (L/h): 8.000

The PA33 of the Evo Line is designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 45 KW

- Pressure (bar): 600

- Capacity (L/h): 15.000

The PA34 of the Evo Line is designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 90 KW

- Pressure (bar): 600

- Capacity (L/h): 24.000

The PA35 of the Evo Line is designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 110 KW

- Pressure (bar): 600

- Capacity (L/h): 35.000

The PA35 of the Evo Line is designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 250 KW

- Pressure (bar): 600

- Capacity (L/h): 45.000

The PA53 is part of the Evo Line, designed with a green approach to reduce environmental impact, ensuring energy efficiency and sustainability in liquid processing.

- Power: 400 KW

- Pressure (bar): 600

- Capacity (L/h): 90.000

The PX pumps can operate with a maximum capacity of 14,000 l/h and a maximum pressure of 80 bar, delicately transferring products up to 30 mm while maintaining their shape unchanged.

- Power: 11 KW

- Pressure (bar): 80

- Capacity (L/h): 7.000

The PX pumps can operate with a maximum capacity of 16,000 l/h and a maximum pressure of 80 bar, delicately transferring products up to 30 mm while maintaining their shape unchanged.

- Power: 22 KW

- Pressure (bar): 80

- Capacity (L/h): 16.000

The TP pumps can operate with a maximum capacity of 12,000 l/h and a maximum pressure of 16 bar, delicately transferring products up to 60 mm while maintaining their shape unchanged.

- Power: 9.2 KW

- Pressure (bar): 16

- Capacity (L/h): 12000

The self-priming piston pump is able to accurately and stably transfer the product without deteriorating it, maintaining its properties unaltered up to a maximum pressure of 70 bar.

- Power: 15 KW

- Pressure (bar): 70

- Capacity (L/h): 6000

The self-priming piston pump is able to accurately and stably transfer the product without deteriorating it, maintaining its properties unaltered up to a maximum pressure of 70 bar.

- Power: 30 KW

- Pressure (bar): 70

- Capacity (L/h): 12000

The self-priming piston pump is able to accurately and stably transfer the product without deteriorating it, maintaining its properties unaltered up to a maximum pressure of 70 bar.

- Power: 55 KW

- Pressure (bar): 70

- Capacity (L/h): 12000

Bertoli centrifugal pumps are particularly used in the tomato sector and are therefore designed for pumping viscous products.

- Power: 5,11,30 KW

- Pressure (bar):

- Capacity (L/h): 120.000

Discover Bertoli's shredding pumps, indispensable for the food industry.

- Power: 30 KW

- Pressure (bar): 6

- Capacity (L/h): 60000

Bertoli BMC colloidal mills are highly efficient machines capable of processing up to 25,000 l/h of product, grinding solids and creating emulsions in applications such as plant-based foods, baby food, hummus, soups, sauces, and seaweed.

- Power: 5,5 KW

- Pressure (bar): 6

- Capacity (L/h): 3000

Bertoli BMC colloidal mills are highly efficient machines capable of processing up to 25,000 l/h of product by grinding solids and creating emulsions in applications such as plant-based foods, baby foods, hummus, soups, sauces, and seaweed.

- Power: 55 KW

- Pressure (bar): 6

- Capacity (L/h): 25000

The Atomo 3.0 pump has been designed with 3 super-efficient pistons and optimized for a reliable scale-up from laboratory testing to production.

- Power: 4 KW

- Pressure (bar): 600

- Capacity (L/h): 650

Do you want to download the catalogue?

Download the catalogue

All the best technology ever designed specifically fou you

Services

Our strengths

Network in the World

Bertoli Homogenizers’ extensive global network ensures high-quality support and services to customers in every corner of the world.

Find a dealer